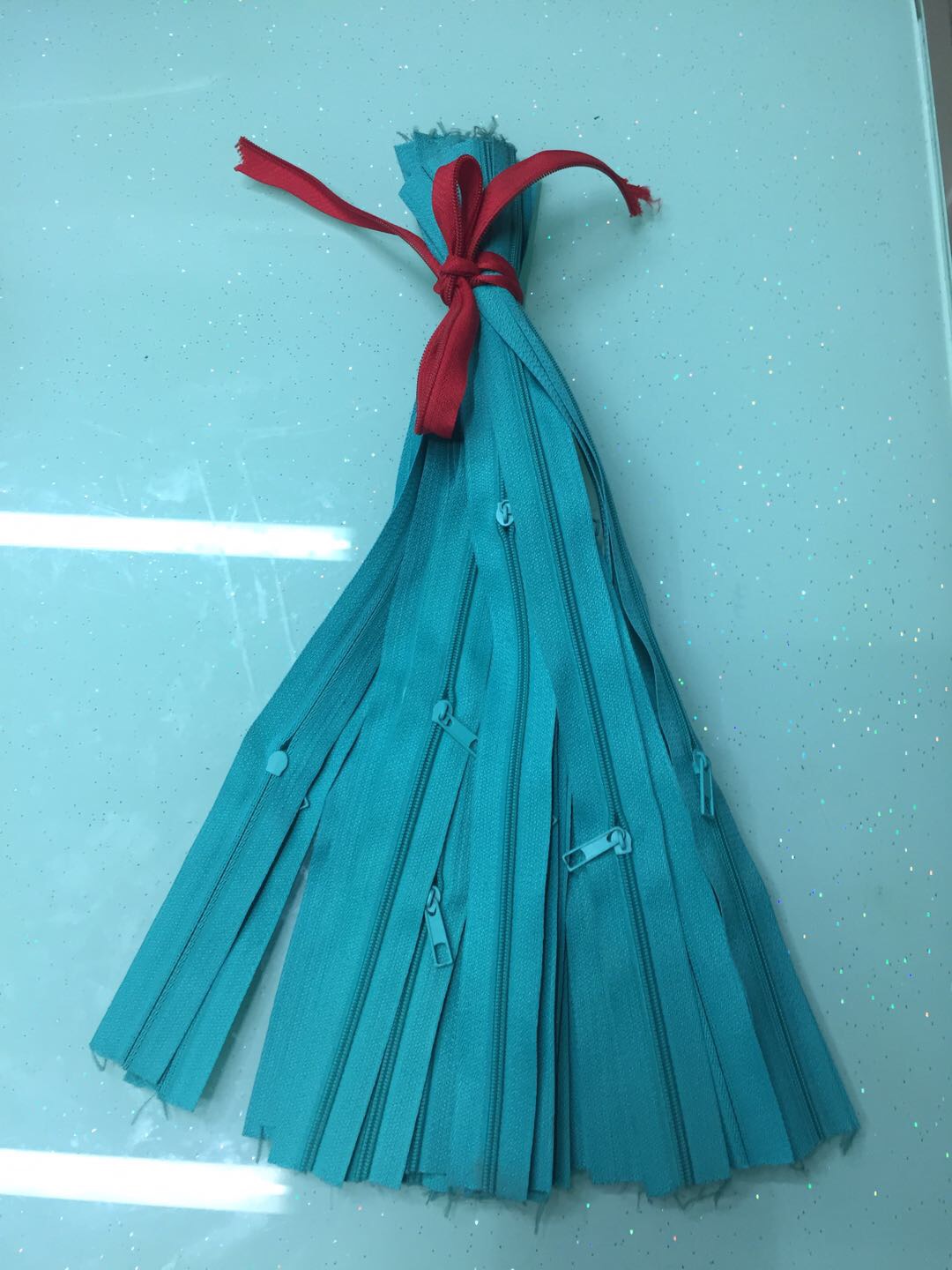

In modern clothing and luggage design, invisible zippers are favored for their understated and elegant features. It can not only add a simple beauty to the overall shape, but also enhance the practicality and grade of the product through its strong functionality. In particular, the invisible zipper made of nylon resin has become the heart of many designers by virtue of its light and strong advantages.

From material selection to production process, nylon resin invisible zipper shows unparalleled technical strength. This material has excellent flexibility and anti-wear ability, which greatly improves the convenience of use while ensuring the service life. In addition, its smooth surface, uniform color and bright, fully fit the high-end market requirements for details.

In order to meet the individual needs of customers, we provide flexible and changeable sample customization services. Whether it is a specific color or size adjustment, or other special specifications, you can get professional answers and support here. The whole process is followed up by an experienced team and combined with advanced production equipment for precise processing and production, so as to ensure that each work is a unique work of art.

More importantly, our factory direct sales model eliminates the additional cost burden of middlemen, so you can enjoy very competitive price concessions without worrying about product quality. All will go through strict inspection procedures before leaving the factory, and strive to deliver the most satisfactory results to each partner.

In terms of practical applications, many customers have achieved remarkable results with the help of this high quality nylon resin invisible zipper. For example, a well-known brand of advanced handbag series will use such components as one of the core components, successfully attracted a large number of consumer attention and received unanimous praise evaluation; there are also many enterprises in the field of sports apparel to choose this product to achieve a lightweight breakthrough while enhancing the degree of durability performance.

If you are looking for an affordable accessory solution that can fully display the brand's characteristics, please don't hesitate to contact us! We will be happy to tailor the perfect invisible zipper solution for you.