Invisible zippers have quietly revolutionized the fashion and textile industries, offering a seamless solution that blends functionality with aesthetic elegance. Among the many types available, nylon resin invisible zippers have emerged as a preferred choice for designers and manufacturers alike. These zippers combine strength, flexibility, and visual subtlety to elevate everything from haute couture to everyday wear. In this article, we’ll explore why nylon resin is the ideal material for invisible zippers, how they’re made, and the many ways customization can enhance your product offerings.

The Hidden Hero of Fashion: How Invisible Zippers Shape Design

At first glance, you might not even notice an invisible zipper — and that’s exactly the point. Designers use them to maintain clean lines and uninterrupted surfaces, especially in garments like dresses, skirts, and tailored pants. Unlike traditional zippers with visible teeth and bulky sliders, invisible zippers are sewn into the seam, lying flat and hidden from view. This subtle integration makes them a favorite among fashion creators who prioritize both aesthetics and function.

What makes nylon resin the material of choice for these zippers? It’s all about balance. Nylon resin offers a unique combination of flexibility and durability, allowing the zipper to bend with the fabric without compromising strength. It also resists wear and tear better than many alternatives, making it suitable for both delicate silks and heavier denim fabrics.

Behind the Seam: What Makes Nylon Resin Invisible Zippers Stand Out

While invisible zippers can be made from various materials such as polyester or metal, nylon resin stands out for its superior performance. Compared to polyester zippers, which can sometimes feel stiff and less forgiving, nylon resin zippers offer a smoother glide and better resistance to snagging. Metal zippers, though durable, are often heavier and can create visible distortions in lighter fabrics — something that’s unacceptable in high-end fashion design.

Nylon resin’s molecular structure allows it to be molded into precise shapes, resulting in teeth that interlock seamlessly and resist jamming. This precision also ensures that the zipper remains truly invisible once sewn in, with no unsightly bulges or gaps. Moreover, the material’s inherent flexibility ensures that the zipper moves with the garment, not against it, contributing to long-lasting wearability.

From Factory to Fabric: The Journey of a Custom Invisible Zipper

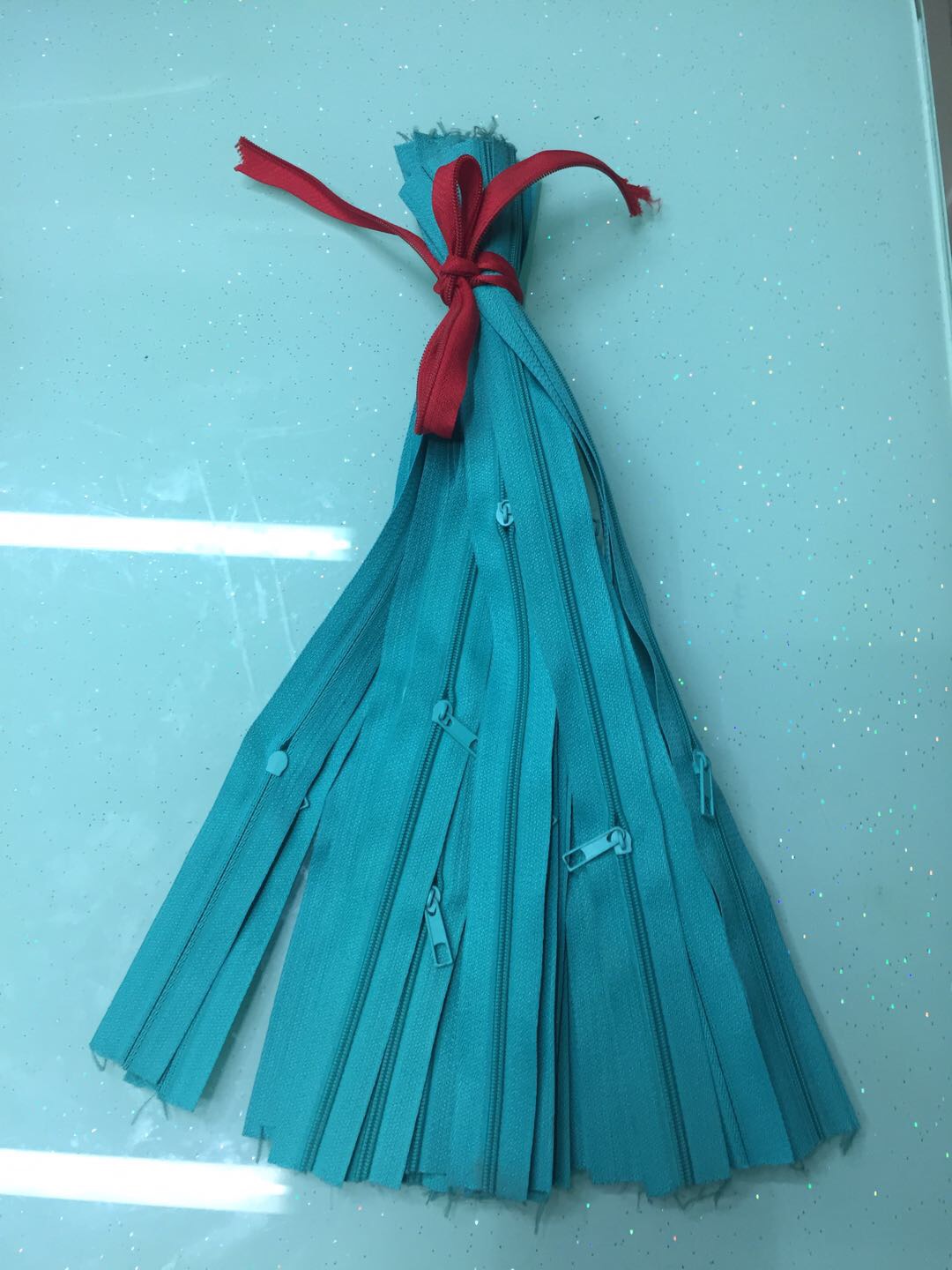

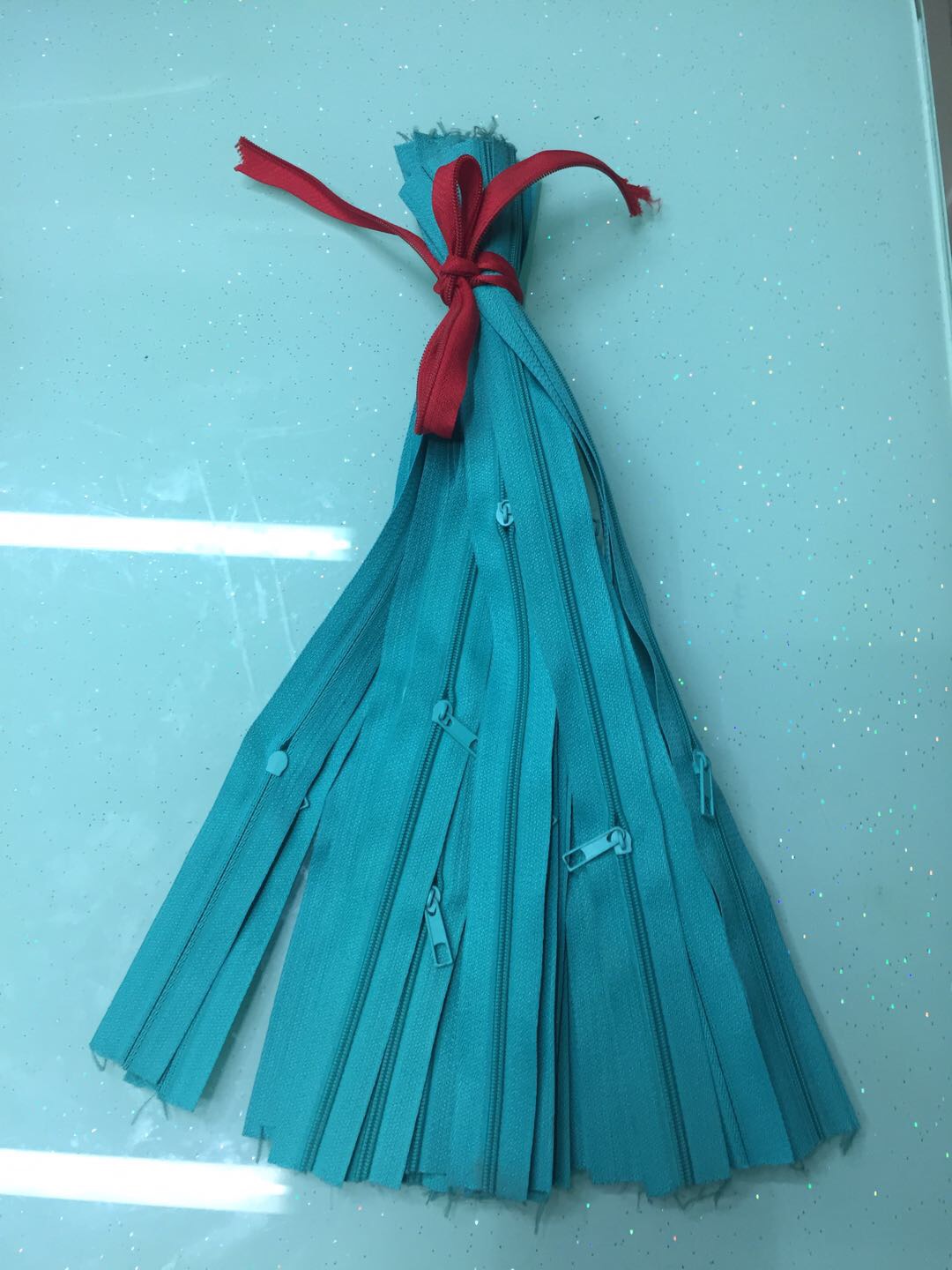

The creation of a nylon resin invisible zipper is a blend of art and science. It starts with high-quality nylon pellets, which are melted and injected into molds to form the individual zipper teeth. These teeth are then precisely aligned and fused onto a continuous tape, typically made of polyester or a similar durable fabric. The tape is dyed to match a wide range of color palettes, ensuring that the zipper blends perfectly with the garment.

Manufacturers understand that no two products are the same. That’s why customization is a key part of the process. From length adjustments to tooth pitch variations and even special slider designs, the possibilities are nearly endless. Whether you need a 6-inch zipper for a sleek pencil skirt or a longer one for a tailored coat, trusted manufacturers can deliver exactly what your design requires — without compromising on quality.

Design Freedom: How Customization Elevates Your Product Offerings

Custom invisible zippers open up a world of possibilities across multiple industries. In fashion, brands are using them to create clean, uninterrupted lines that enhance the silhouette of a garment. In home décor, they’re used in cushion covers and slipcovers to maintain a polished look without visible closures. Even in accessories like handbags and wallets, invisible zippers provide a sleek, modern finish.

Color matching is one of the most popular customization options. Whether you’re working with a bold red dress or a neutral beige trench coat, having a zipper that matches the fabric ensures a seamless appearance. Some manufacturers even offer special finishes, such as matte or glossy coatings, to further enhance the zipper’s visual integration into the design.

When Quality Meets Precision: Why Trusting the Manufacturer Matters

While many companies offer invisible zippers, not all are created equal. The difference lies in the manufacturing process. Reputable manufacturers use advanced machinery and rigorous quality control protocols to ensure every zipper meets high standards of performance and appearance. This includes testing for smooth operation, durability under repeated use, and resistance to fading or discoloration.

When choosing a manufacturer, it’s essential to consider their experience, production capabilities, and commitment to quality. Visiting the factory or requesting detailed product samples can help verify that the zippers will perform as expected in real-world applications. Trusting a reliable manufacturer means you can confidently integrate invisible zippers into your designs without worrying about defects or inconsistencies.

Real-World Applications: How Brands Are Using Invisible Zippers Creatively

Leading fashion houses have embraced invisible zippers not just for their functionality, but for their creative potential. Some designers have used them to create “invisible” entry points in garments, allowing for surprising transformations — such as a dress that converts into a skirt with a single zip. Others have placed zippers in unconventional locations, like along the back seam of a jacket or hidden within a pleat, to add a touch of modernity and surprise.

In the home and luggage industries, invisible zippers are used to maintain clean aesthetics while offering secure closures. For example, luxury luggage brands use them to keep the exterior of their bags sleek and uncluttered, while interior compartments remain securely closed. In upholstery, invisible zippers allow for easy removal of cushion covers for cleaning, without compromising the design of the furniture.

The Future of Fastening: Trends in Invisible Zipper Technology

As technology and sustainability converge, invisible zippers are evolving to meet new demands. Eco-conscious brands are exploring biodegradable or recycled nylon options, ensuring that even the smallest components of a garment align with their environmental values. Meanwhile, the rise of smart textiles and wearable technology is pushing the development of zippers that can integrate seamlessly with electronic components, such as sensors or charging ports.

Innovations in zipper design are also emerging. Some manufacturers are experimenting with magnetic sliders or heat-sealed closures that offer alternative fastening solutions while maintaining the invisible aesthetic. These developments suggest that the future of invisible zippers is not only about hiding from view but also about enhancing functionality in ways we’ve yet to imagine.

Choosing the Right Partner: How to Work Directly with Invisible Zipper Manufacturers

Collaborating directly with a manufacturer can offer significant advantages, especially when it comes to customization and cost efficiency. To ensure a successful partnership, it’s crucial to communicate your design vision clearly, including specifications like color, size, tooth pitch, and any special features. Providing fabric swatches or samples can help the manufacturer match the zipper precisely to your materials.

Flexibility in order quantities and lead times is another important consideration. Many trusted manufacturers offer both small-batch trials and large-scale production runs, allowing brands to test the product before committing to mass orders. Building a long-term relationship with a reliable supplier not only ensures consistent quality but also opens the door to future innovations and exclusive design elements.

Whether you're crafting a high-fashion garment, designing a minimalist bag, or creating sleek home décor, nylon resin invisible zippers offer a blend of form and function that’s hard to beat. With the right manufacturer, you can bring your vision to life — one seamless zip at a time.