The Hidden Power of Perfect Closures: Exploring Nylon Resin Invisible Zippers from the Source

When it comes to high-quality garment construction, the smallest details can make the biggest difference. Among these, the zipper often plays a subtle yet pivotal role. Nylon resin invisible zippers have become a staple in modern fashion design due to their sleek appearance and superior functionality. Whether you're a fashion designer, apparel manufacturer, or product developer, understanding the value of sourcing these zippers directly from the factory can significantly elevate your product’s quality and market appeal.

Why Invisible Zippers Are a Game-Changer in Modern Fashion Design

Invisible zippers are not just about function—they're about aesthetics. Unlike traditional zippers that draw attention, invisible zippers blend seamlessly into the garment, allowing the fabric’s texture and design to take center stage. This makes them particularly popular in tailored dresses, skirts, and high-end outerwear. The use of nylon resin in these zippers enhances their durability without compromising on their lightweight and flexible nature, making them ideal for a wide range of garments.

Behind the Scenes: How Nylon Resin Zippers Are Made

The production of nylon resin invisible zippers is a precise process that combines advanced engineering with traditional craftsmanship. Starting with high-grade nylon pellets, the teeth are injection-molded directly onto the tape, ensuring a secure and uniform fit. This method eliminates the inconsistencies found in stitched or metal zippers. The result is a zipper that is not only visually discreet but also resistant to snagging and wear over time.

The Benefits of Going Direct: Why Sourcing from Manufacturers Matters

By sourcing directly from manufacturers, brands and designers can unlock significant advantages. From cost savings to faster turnaround times, direct procurement eliminates middlemen and streamlines the supply chain. More importantly, working directly with factories opens the door to customized solutions. Whether you need a specific color, length, or even a branded puller, manufacturers are often more flexible when dealing directly with end-users.

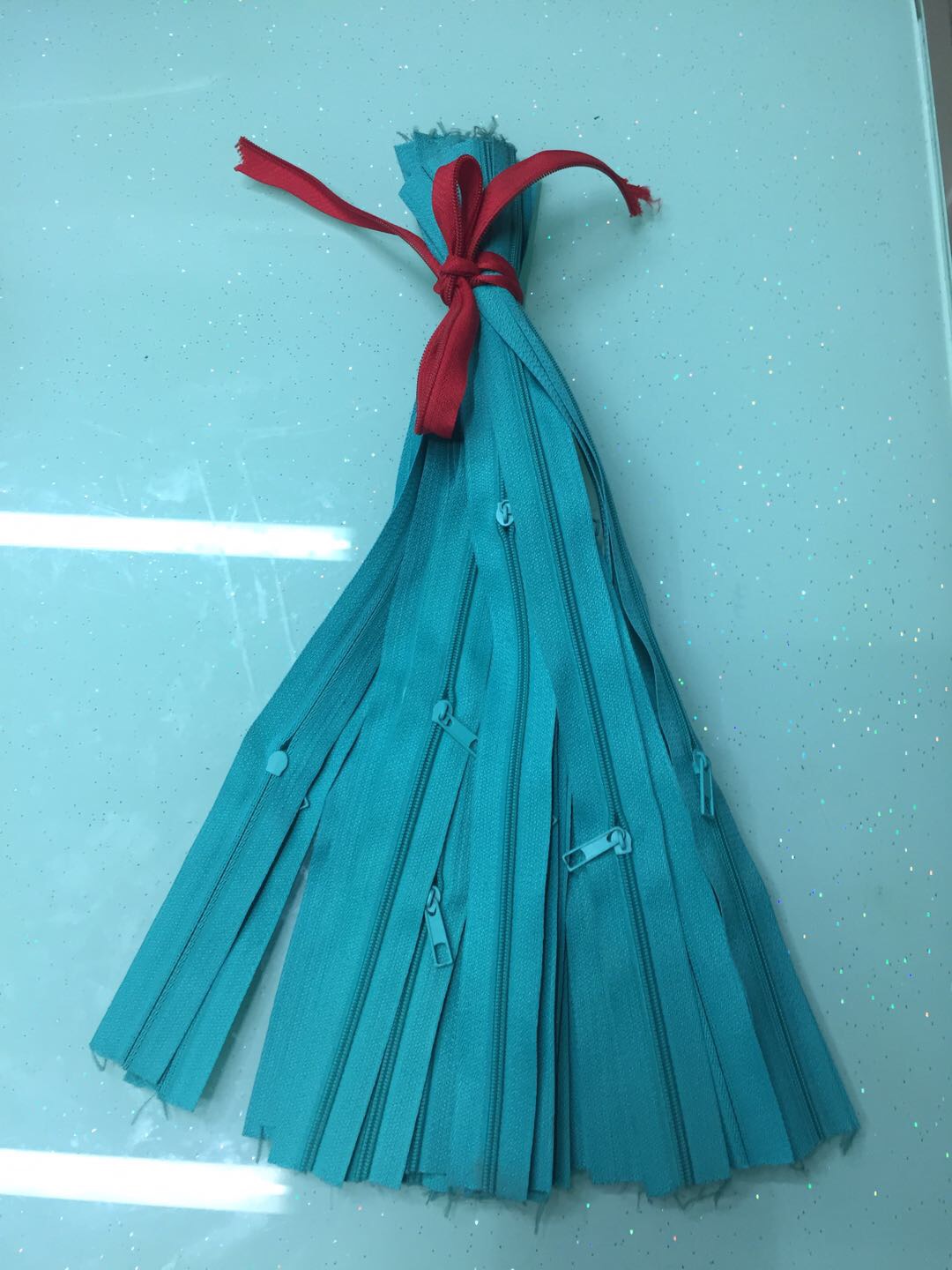

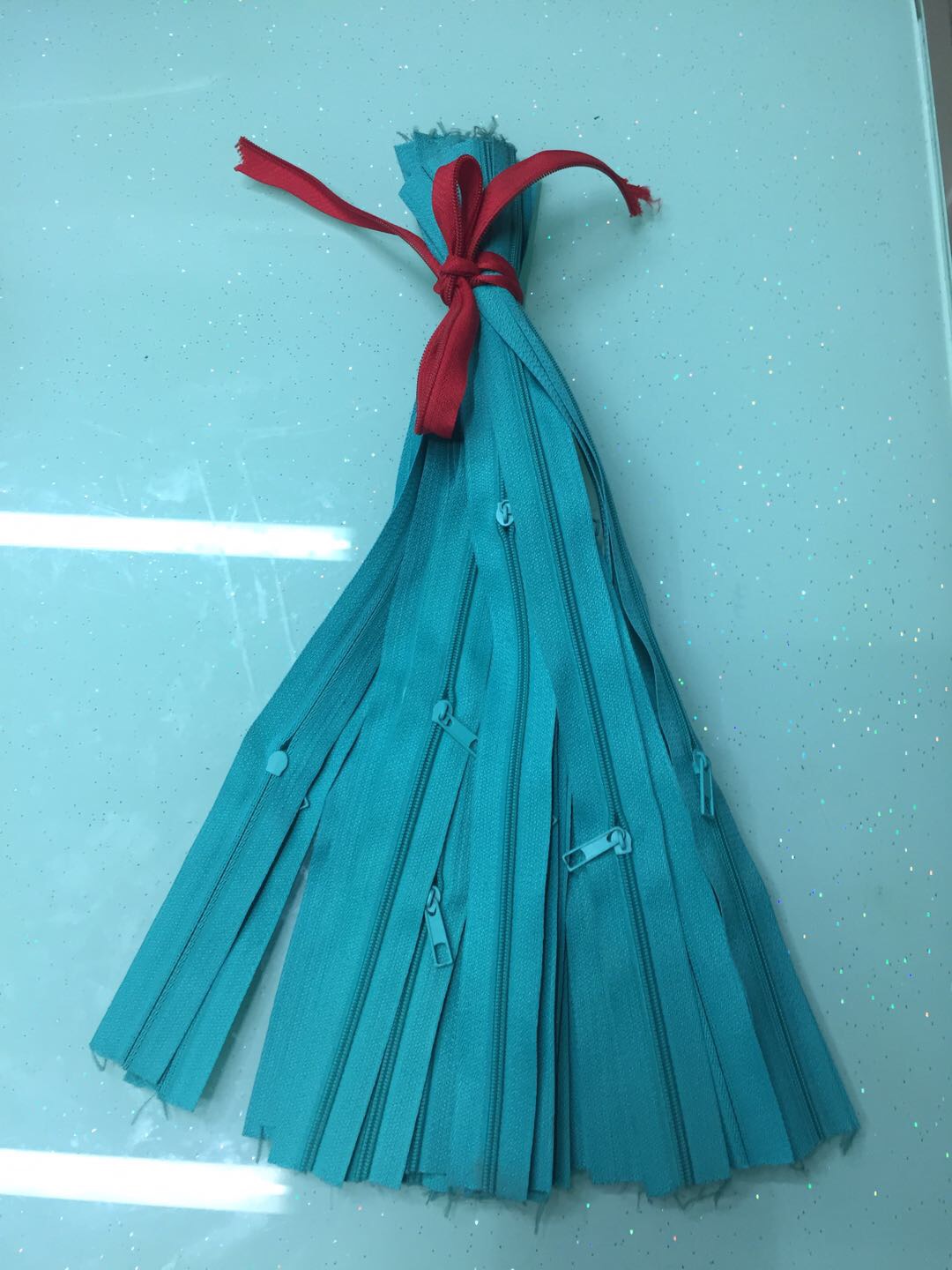

Inside the Sample Box: What You’ll Discover When You Request a Nylon Resin Zipper Sample

Before placing a bulk order, requesting a sample pack is essential. A well-curated sample set includes various colors, sizes, and tooth configurations, allowing you to test how each zipper performs in real-world applications. You'll be able to assess the smoothness of the slider, the tensile strength of the teeth, and the overall durability of the zipper under repeated use. These firsthand experiences are invaluable when making final decisions for your product line.

Customization Unleashed: Making Invisible Zippers Your Brand’s Signature Touch

While invisible zippers are designed to disappear, they can also serve as a subtle yet powerful branding tool. Many manufacturers offer custom color matching, embossed pullers, and even branded tape options. These customizations allow designers to align zippers with their brand identity, enhancing the perceived value of the garment. A luxury brand, for example, might choose a matte black zipper with a gold-toned puller to complement its label’s aesthetic.

From Factory Floor to Fashion Studio: The Journey of a Nylon Resin Invisible Zipper

The journey of a nylon resin zipper begins in the factory, where every step—from raw material selection to packaging—is monitored for consistency and quality. Quality control checks are performed at multiple stages to ensure that each zipper meets international standards. Once completed, the zippers are carefully packed and shipped directly to designers or manufacturers, maintaining integrity throughout the supply chain.

What Buyers Should Look for When Evaluating Nylon Resin Zipper Samples

Evaluating zipper samples requires a keen eye for detail. Start by testing the zipper’s opening and closing mechanism—does it glide smoothly without catching? Next, examine the teeth: are they evenly spaced and securely attached to the tape? The puller should be sturdy and resistant to wobbling or breaking. Color consistency and tape flexibility are also crucial, especially for garments that require frequent washing or dry cleaning.

Trends in Invisible Zipper Design: What’s New and What’s Next

As fashion continues to evolve, so too do the components that support it. Invisible zippers are now being designed with sustainability in mind, using recycled nylon and biodegradable resins. Additionally, smart textiles and wearable tech are pushing the boundaries of zipper design, integrating features like magnetic closures and touch-sensitive sliders. The future of invisible zippers lies in their ability to adapt to both environmental concerns and technological advancements, making them more versatile than ever.