Discover the perfect blend of fashion and function with high-quality nylon resin invisible zippers, tailored to your brand’s exact specifications. Explore how direct collaboration with manufacturers can elevate your product design and streamline production.

The Perfect Fusion of Fashion and Function

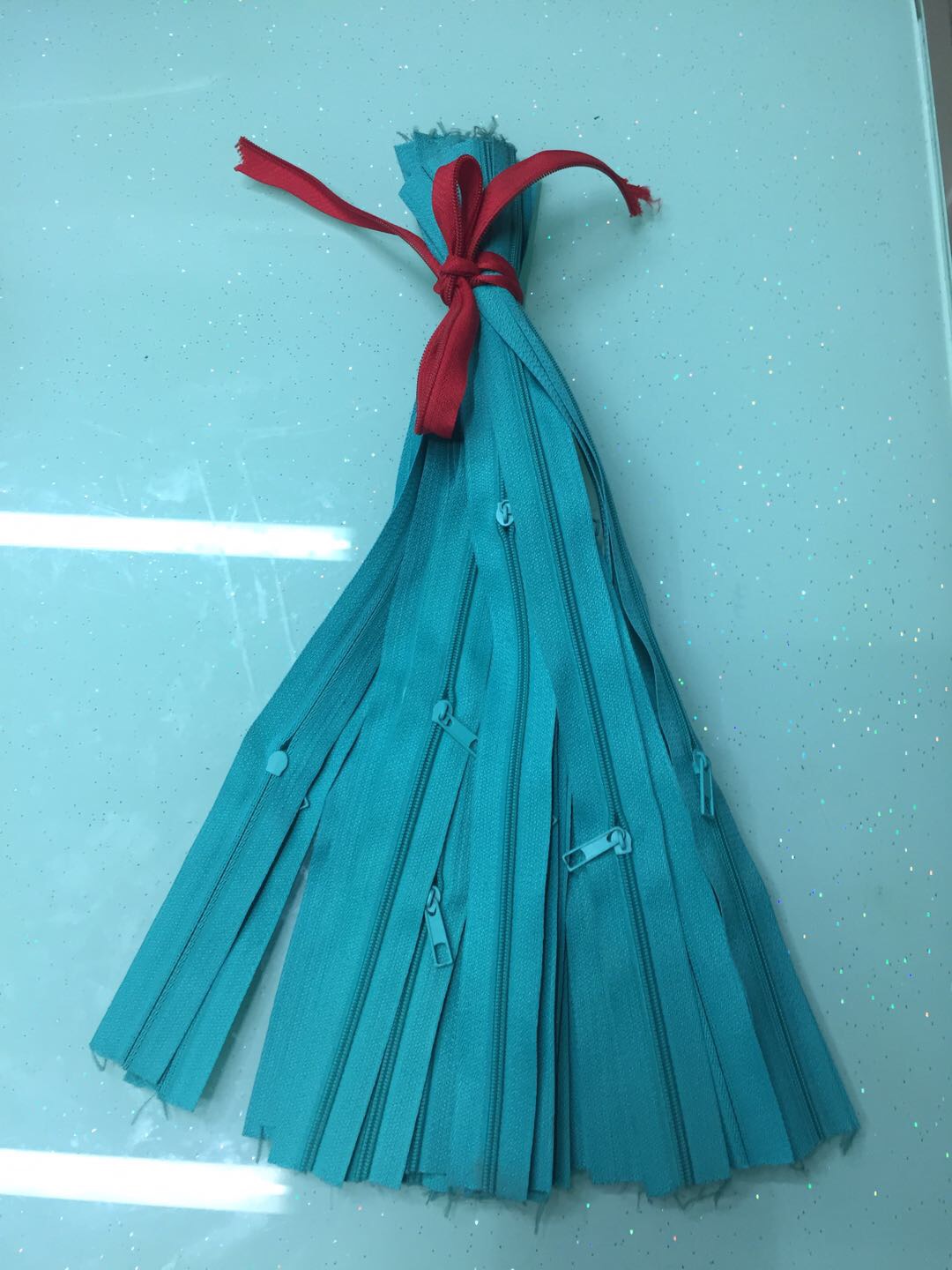

Invisible zippers have become a staple in modern fashion and functional design, offering a clean and unobtrusive closure solution that enhances both aesthetics and usability. From elegant dresses to rugged outdoor gear, these zippers blend seamlessly into garments and products without compromising on strength or performance.

Nylon resin is a preferred material for invisible zippers due to its exceptional durability and flexibility. Unlike traditional metal zippers, nylon resin zippers offer a lighter weight and smoother glide, while maintaining resistance to wear and tear. Their translucent or dyed teeth can be matched precisely to fabric colors, making them virtually disappear into the design.

Whether used in high-end fashion, sportswear, or even home décor, invisible zippers provide a professional finish that speaks to the attention to detail of any brand. Designers appreciate the clean lines they offer, and consumers benefit from the comfort and functionality they provide.

Why Direct from Manufacturers Makes a Difference

Working directly with manufacturers opens the door to superior quality, cost efficiency, and customization. When you bypass intermediaries, you gain access to the source of innovation and craftsmanship—ensuring that every zipper meets your exacting standards.

Manufacturers who specialize in nylon resin zippers implement rigorous quality control measures throughout the production process. From raw material selection to final inspection, each zipper is tested for smoothness, durability, and color accuracy. This ensures that every batch maintains consistent performance and appearance.

Moreover, direct communication with manufacturers allows for faster response times, clearer specifications, and more cost-effective solutions. Brands can avoid markup fees and streamline their supply chain by building a direct relationship with a trusted partner.

Customization: Tailor Every Detail to Your Brand

One of the most compelling benefits of working directly with manufacturers is the ability to customize zippers to align with your brand identity. Whether you need a specific Pantone color, unique puller design, or precise tooth spacing, manufacturers can accommodate a wide range of specifications.

Customization extends beyond aesthetics. Brands can choose from various zipper lengths, widths, and closure types to suit different applications. For example, a luxury fashion brand might opt for a matte black zipper with a discreet pull tab, while a sportswear company may prioritize high tensile strength and water-resistant coatings.

Many brands have successfully leveraged custom zippers to differentiate their products in competitive markets. From bespoke bridal gowns to technical backpacks, the right zipper can enhance the perceived value and usability of the end product.

Requesting Samples: A Smart Step Toward Confidence

Before placing a large order, it's essential to request samples to evaluate performance and appearance. A physical sample allows designers and product managers to test the zipper in real-world conditions, ensuring it meets both functional and aesthetic requirements.

Manufacturers typically offer a streamlined process for sample requests, enabling brands to receive prototypes quickly and efficiently. When evaluating samples, key criteria include the smoothness of the slider, the durability of the teeth, and the zipper's ability to remain securely closed under stress.

This step not only ensures product quality but also builds trust with the manufacturer. By testing samples, brands can confirm that the supplier understands their unique needs and can consistently deliver high-quality zippers.

Building Long-Term Partnerships with Manufacturers

Establishing a long-term relationship with a zipper manufacturer can lead to greater efficiency, innovation, and reliability. Open communication is key—brands should clearly articulate their expectations, including technical specifications, delivery timelines, and quality standards.

Transparency in the manufacturing process also plays a crucial role in building trust. Reputable manufacturers often provide detailed information about their production methods, certifications, and environmental practices. This allows brands to ensure that their partners align with their values and industry standards.

Regular feedback and iterative improvements can further enhance the collaboration. By maintaining a continuous dialogue, brands can adapt to changing market demands and refine their products over time.

Looking Ahead: The Future of Invisible Zippers

As technology and sustainability continue to shape the textile industry, invisible zippers are evolving to meet new demands. Innovations such as smart zippers with integrated sensors are emerging in the wearable tech space, offering functionality beyond closure—like tracking movement or monitoring vital signs.

At the same time, the push for eco-friendly materials has led to the development of biodegradable and recycled nylon resins. These sustainable alternatives provide the same performance benefits while reducing environmental impact, appealing to both conscious consumers and forward-thinking brands.

Industry experts predict that future zipper designs will focus on even more seamless integration into smart garments and high-performance textiles, making them an essential component of next-generation apparel and accessories.