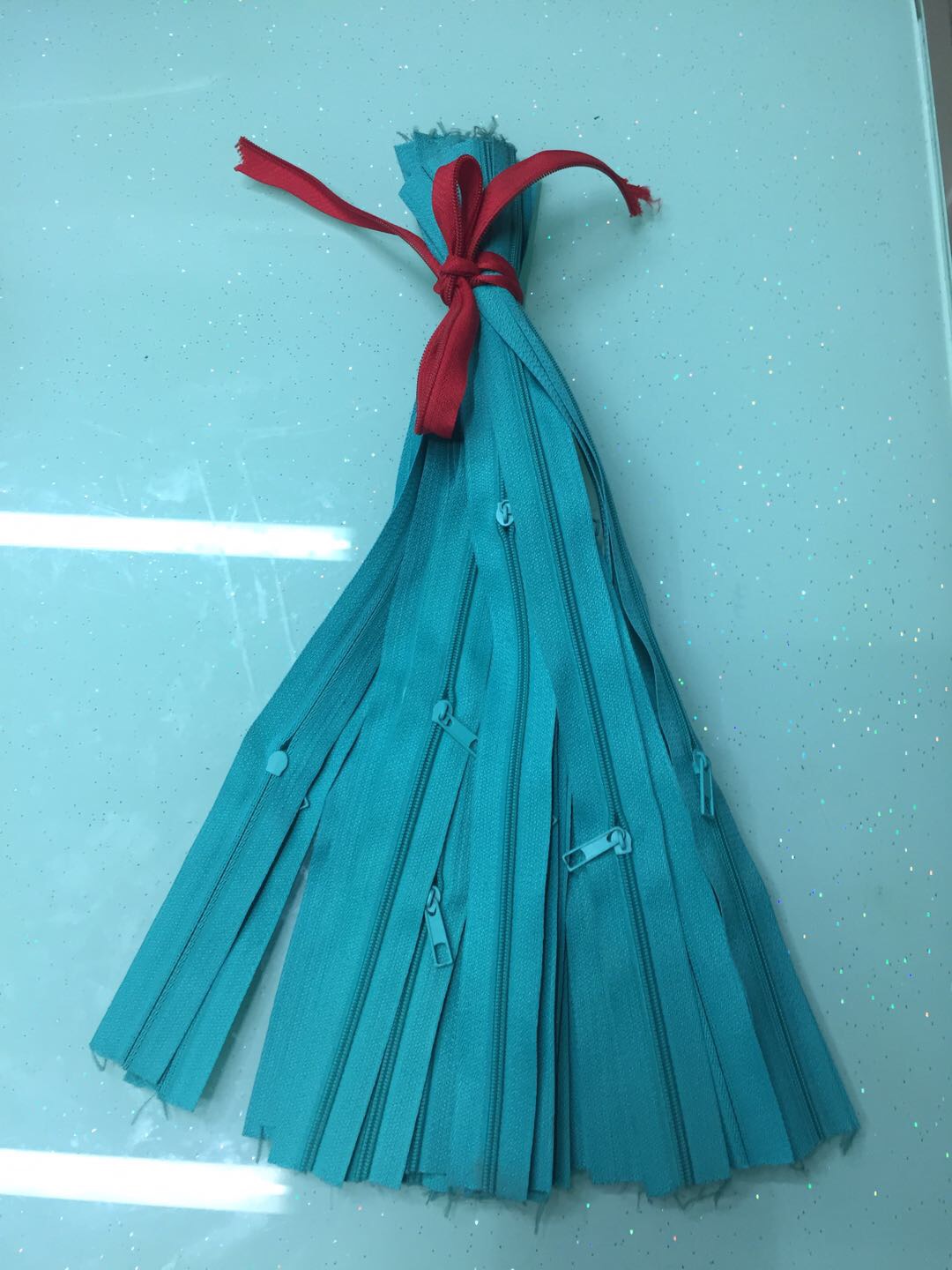

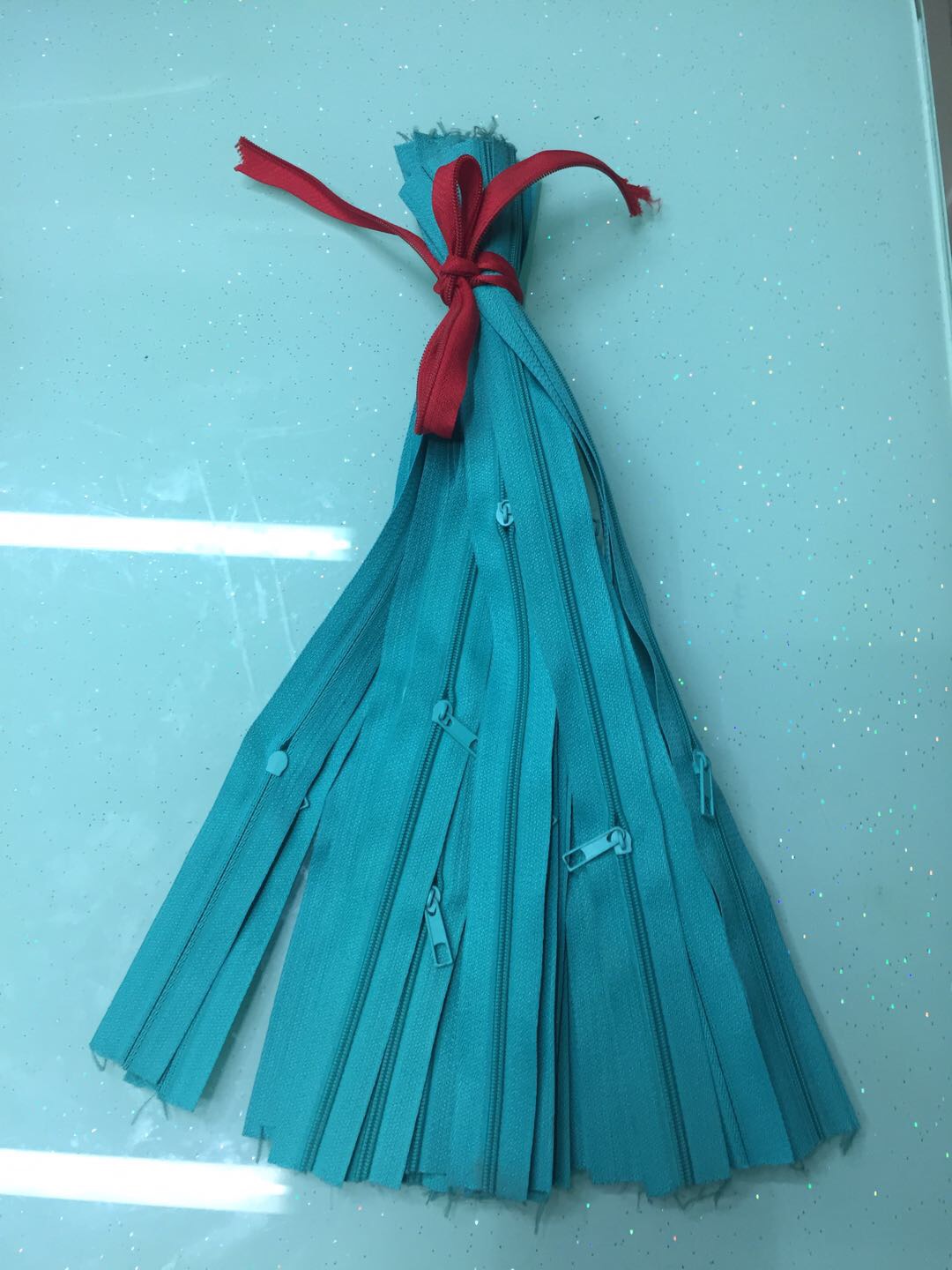

Nylon Resin Invisible Zippers – Manufacturer Direct Samples & Custom Solutions

In the world of high fashion, perfection lies in the unseen. A flawless silhouette, a clean seam, an uninterrupted line—these are not accidents. They are the result of meticulous craftsmanship and one often-overlooked hero: the invisible zipper. And today, a quiet revolution is reshaping how designers close their garments. Welcome to the era of nylon resin invisible zippers—where engineering meets elegance.

When Invisibility Meets Craftsmanship: Redefining the Seam

Have you ever admired a sleek evening gown or a minimalist trench coat and wondered how it stays closed without disrupting its pristine lines? The answer hides in plain sight—literally. Behind the scenes of top-tier couture, designers are turning to nylon resin invisible zippers as the secret weapon for achieving that elusive “no-seam” look.

Unlike traditional metal or coil zippers that create visible ridges and distort fabric flow, these advanced closures nestle seamlessly into garment edges. Once sewn, they vanish—leaving only smooth continuity. From bias-cut silk gowns to structured tailoring, this subtle detail elevates the entire aesthetic, transforming good design into exceptional wearability.

From Factory Floor to Fashion Studio: Power in Direct Manufacturing

What sets our nylon resin invisible zippers apart isn’t just performance—it’s provenance. We manufacture every inch in-house, overseeing each stage from raw material extrusion to final packaging. This vertical integration ensures unmatched consistency in tooth alignment, tape tension, and slider precision.

By cutting out middlemen, we deliver directly to designers, atelier owners, and emerging labels—offering wholesale pricing without compromising quality. More importantly, it means faster turnaround times. Need a sample in five days? Done. Want to adjust your order based on fit feedback? No delays, no red tape. Just responsive, agile support tailored to modern fashion cycles.

The Triad of Performance: Smooth, Strong, and Supple

Invisible doesn’t mean fragile. On the contrary, nylon resin technology delivers a rare balance of strength, flexibility, and glide. At the molecular level, engineered resins resist UV degradation and hydrolysis—critical for swimwear, outerwear, and garments exposed to humidity or frequent washing.

We put them to the test: after 50 industrial washes, our zippers retain 98% of their original luster and function flawlessly. Compare that to standard polyesters, which often show fraying teeth or sticky sliders after half the cycle. Whether used in bridal gowns requiring lifelong integrity or activewear demanding daily resilience, these zippers perform—quietly and consistently.

Built for Your Brand DNA: Beyond Off-the-Shelf

Your brand has a voice. Why should your hardware be generic? Our customization suite empowers you to embed identity into every closure. Choose from 3mm to 10mm tooth widths, match any Pantone shade—even fluorescent or matte finishes—and add functional flair with metallic coatings or glow-in-the-dark elements.

One independent designer recently launched a sold-out capsule collection featuring rainbow-gradient invisible zippers, laser-etched with her logo on each puller. What could have been a hidden component became a signature touch—one customers noticed, photographed, and shared. That’s the power of bespoke detailing.

The Ripple Effect of a Sample: How One Change Transformed a Label

Take the story of Lume, a rising women’s wear brand struggling with customer complaints about "cheap-feeling" backs on their pencil skirts. Skeptical but curious, they requested free samples of our 5mm navy resin invisible zippers. Within three days, their team tested them across prototypes. The result? A smoother closure, cleaner finish, and dramatically improved perceived value.

After switching across their core line, post-purchase surveys revealed a 47% increase in comments praising the brand’s “attention to detail.” All from a single, strategic upgrade. That’s the leverage a well-chosen zipper provides—a small investment with outsized returns in quality perception.

The Hidden Sustainability Advantage

Fashion’s future is responsible—and surprisingly, invisible zippers play a role. Lightweight by design, they reduce fabric stress and garment weight, contributing to lower shipping emissions. Their durability extends clothing life, reducing replacements. Plus, precise manufacturing minimizes defects, slashing rework and waste.

Every time a seam doesn’t pucker, a zipper doesn’t jam, or a dress survives another dry clean intact, resources are preserved. It’s sustainability not shouted from billboards, but woven into construction—one silent, smart choice at a time.

Step Into the Future of Seamless Design

The question isn’t whether your next collection can afford to use premium invisible zippers—it’s whether it can afford not to. With free sample kits available now, there’s zero risk and infinite potential. Simply reach out, describe your vision, and receive tailored options in days, backed by technical guidance from our apparel engineers.

If a zipper can make a garment look three times more luxurious… what are you still sewing with?