Backstage at a Paris fashion week show, a stylist holds her breath as a model steps into a silk crepe gown. The seam runs down the spine like a whisper. No one notices the closure—because it’s not meant to be seen. As the final pin is removed, the designer smiles. The zipper didn’t just work—it vanished. In that moment, the true power of the invisible zipper reveals itself: it’s not about hiding a fastener, but about preserving the purity of design.

When Stitches Disappear: The Hidden Force Redefining Fashion Design

Invisible zippers have quietly become the unsung heroes of modern apparel. From haute couture gowns to minimalist streetwear, they enable clean lines and uninterrupted silhouettes. But not all invisible zippers are created equal. The breakthrough lies in material science—specifically, high-performance nylon resin. Unlike traditional metal or standard plastic zippers, nylon resin offers unmatched flexibility, strength, and aesthetic subtlety. It drapes with the fabric, bends without breaking, and most importantly, disappears when stitched correctly. This isn’t just a closure; it’s an extension of the designer’s vision.

From Factory Floor to Final Stitch: Why Manufacturing Origin Shapes Excellence

The journey of a superior invisible zipper starts long before it reaches the sewing table. When designers source directly from manufacturers—bypassing layers of distributors—they gain access to tighter tolerances, faster iterations, and transparent pricing. While middlemen often stretch lead times and limit customization, direct partnerships allow for agile development cycles. Imagine requesting a 3mm shorter puller or a matte finish update—and seeing it in a sample within days, not weeks. Behind every smooth glide is a process of precision injection molding, where molten nylon resin flows into micro-engineered dies at exact temperatures, ensuring uniform tooth formation and consistent coil integrity across thousands of meters.

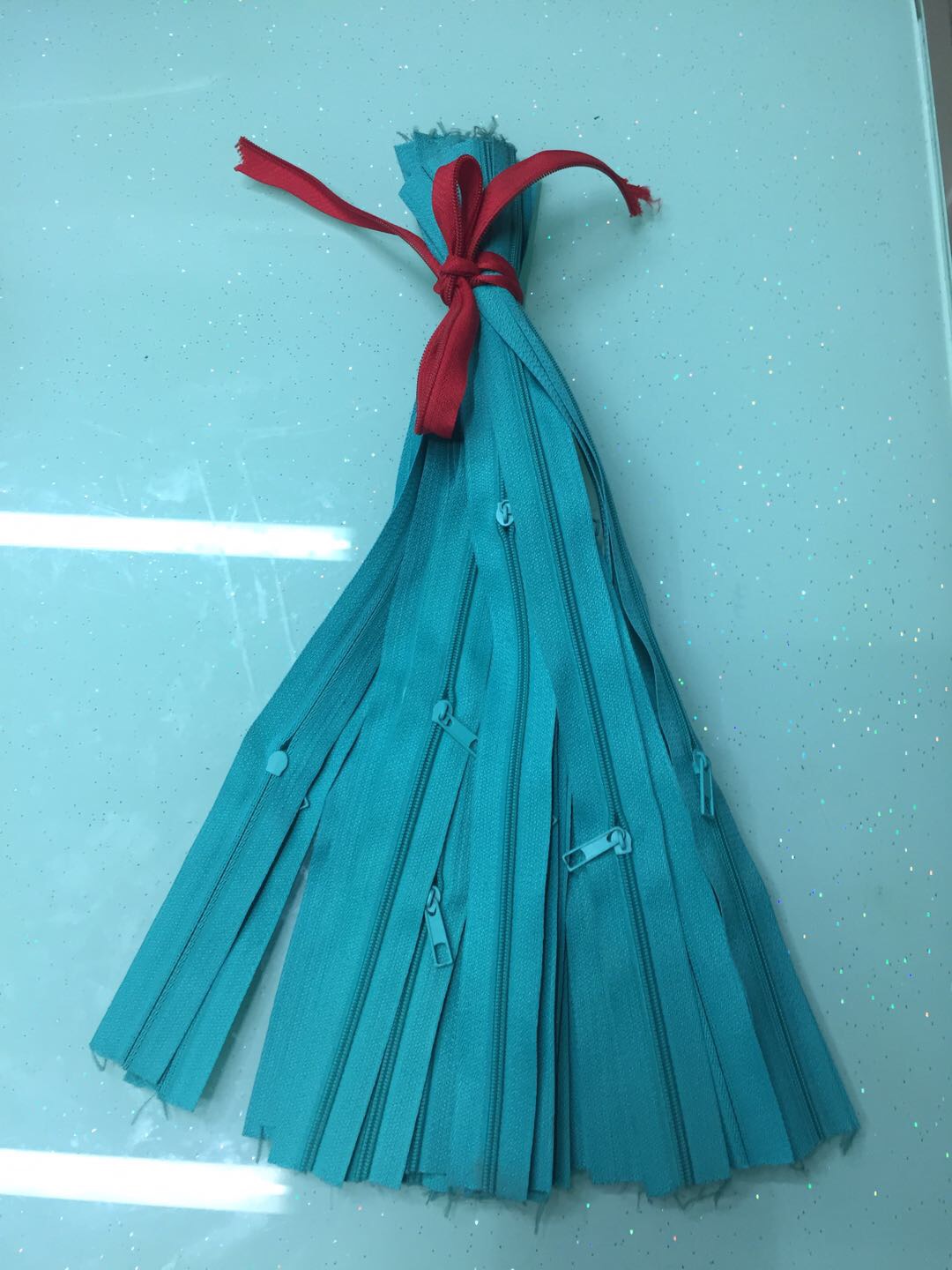

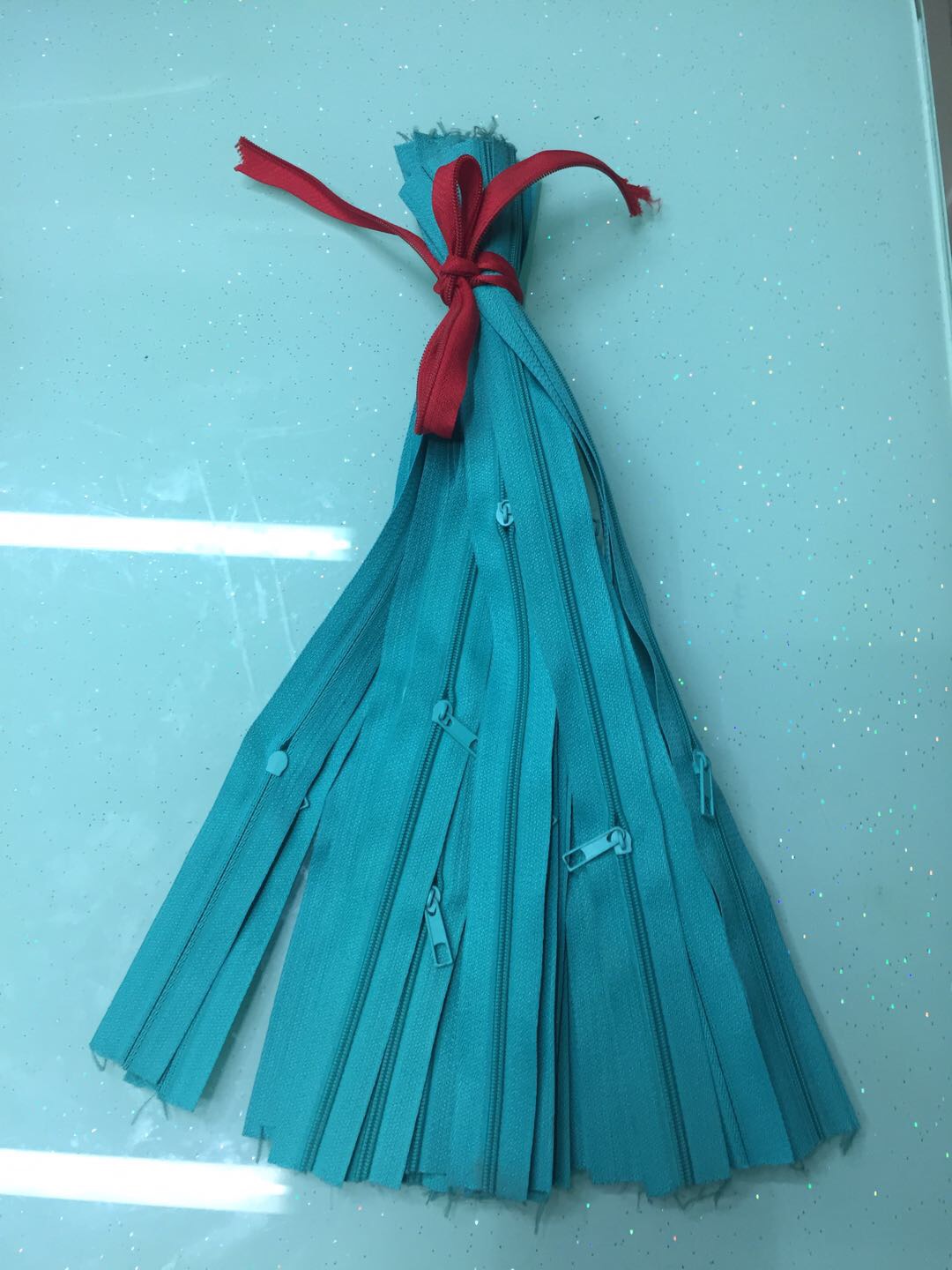

Beyond Color: Unlocking the Full Spectrum of Customization

True personalization goes far beyond matching a Pantone swatch. Today’s leading manufacturers empower designers to tailor every detail: zipper length calibrated to millimeters, variable tooth pitch for different fabric weights, custom puller shapes—from sleek teardrops to branded geometric icons—and even interchangeable pull tabs made from recycled metal or bio-based resins. One emerging designer used a signature gunmetal-gray matte puller across her entire debut collection, turning a functional component into a brand hallmark. And with low minimum order quantities, experimenting with new variations carries less risk than ever. A single prototype run can validate a concept before full-scale production, accelerating time-to-market without compromising originality.

The Science of Flexibility: Why Nylon Resin Dominates High-End Apparel

Nylon resin isn’t chosen for looks alone—it’s engineered for performance. Tested rigorously for UV resistance, hydrolysis stability, and sub-zero flexibility, these zippers maintain smooth operation after 10,000+ open-close cycles. Compare this to metal zippers, which can corrode, snag, or add unwanted weight—especially problematic in lightweight dresses or performance outerwear. The inherent lightness and soft hand of nylon resin make it ideal for intimate garments like lingerie, where comfort is non-negotiable. Yet it’s equally at home in structured coats, adapting to movement without distorting seams. This duality—strength and suppleness—is what makes it the material of choice for discerning designers worldwide.

Sewing the Unseen: Mastering the Craft of True Invisibility

A perfect invisible zipper doesn’t just depend on quality materials—it demands precise craftsmanship. Using a specialized coiler foot ensures the teeth nest perfectly against the seam allowance, while balanced thread tension prevents puckering. Fabric choice also plays a role: sheer chiffon requires finer stitching than sturdy gabardine. Even packaging matters. Premium suppliers use rigid spools and protective sleeves to prevent twisting during transit—a small detail that preserves the zipper’s shape until it hits the cutting table. These nuances separate amateur results from professional-grade finishes.

The Quiet Revolution: Where Sustainability Meets Innovation

As fashion embraces circularity, the role of materials becomes even more critical. Nylon resin, particularly when derived from recycled feedstocks, aligns with eco-conscious values. Advanced manufacturing techniques now reduce energy consumption during extrusion and molding, lowering carbon output per meter. Future advancements point toward digital dyeing processes that minimize water waste—critical in an industry historically plagued by textile pollution. Choosing responsibly sourced invisible zippers isn’t just ethical—it’s strategic, resonating with consumers who value both beauty and responsibility.

Hold Your Vision in Your Hands: Begin Your Custom Zipper Journey

Starting your custom zipper project feels less like placing an order and more like selecting shades from a designer’s palette. Choose your length, pick a puller style, match your fabric tone—or go bold with contrast. Request physical samples to test drape and luster under natural light. Adjust, refine, confirm. With intuitive support and rapid turnaround, the barrier between idea and reality has never been thinner. Try a different pull tab. Experiment with a hidden glow-in-the-dark coil. Sometimes, changing one seemingly minor detail can redefine an entire garment.

“The best function is one that people don’t notice. When the zipper disappears, the design speaks.”

— Anonymous Designer’s Notebook