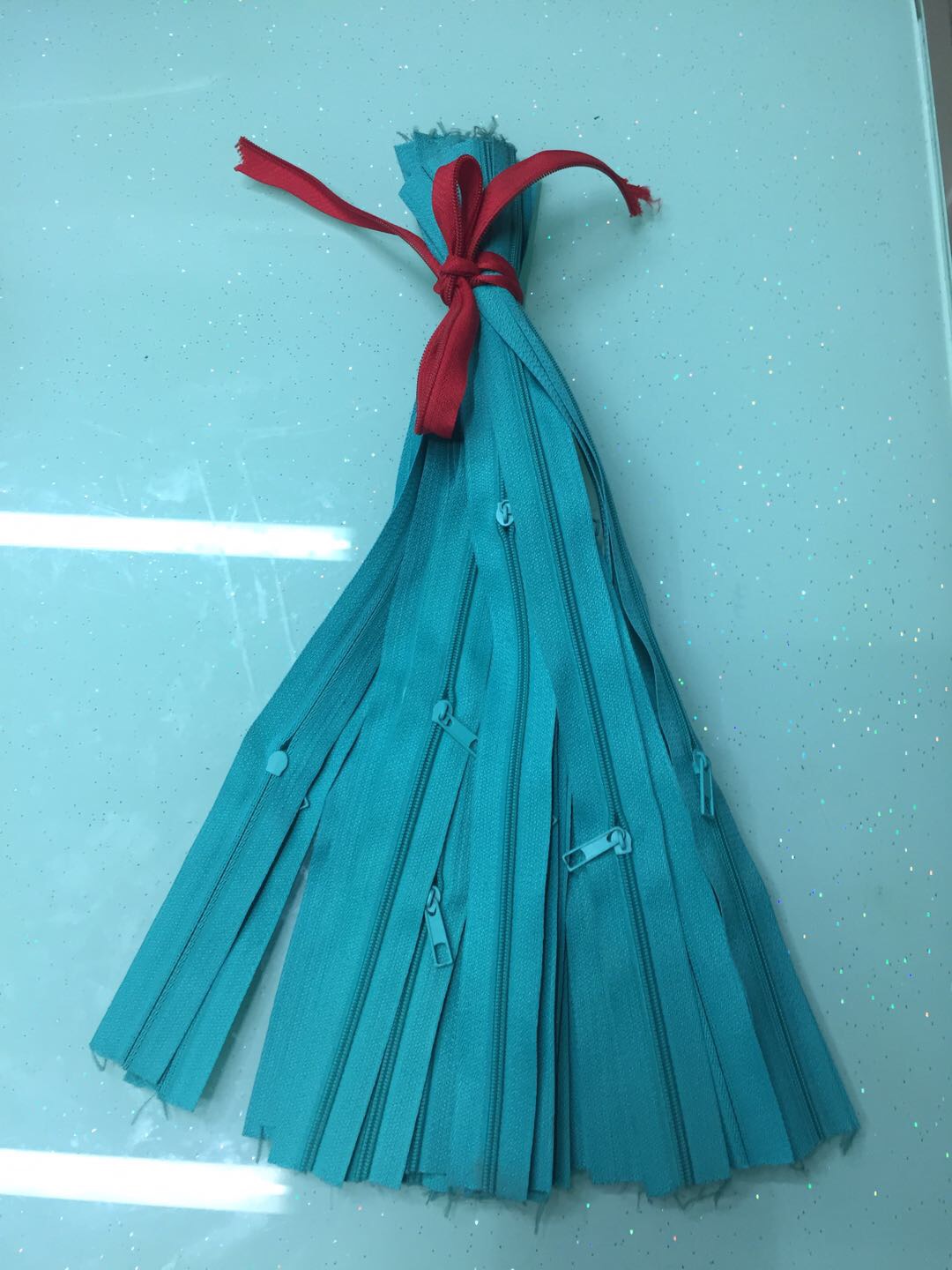

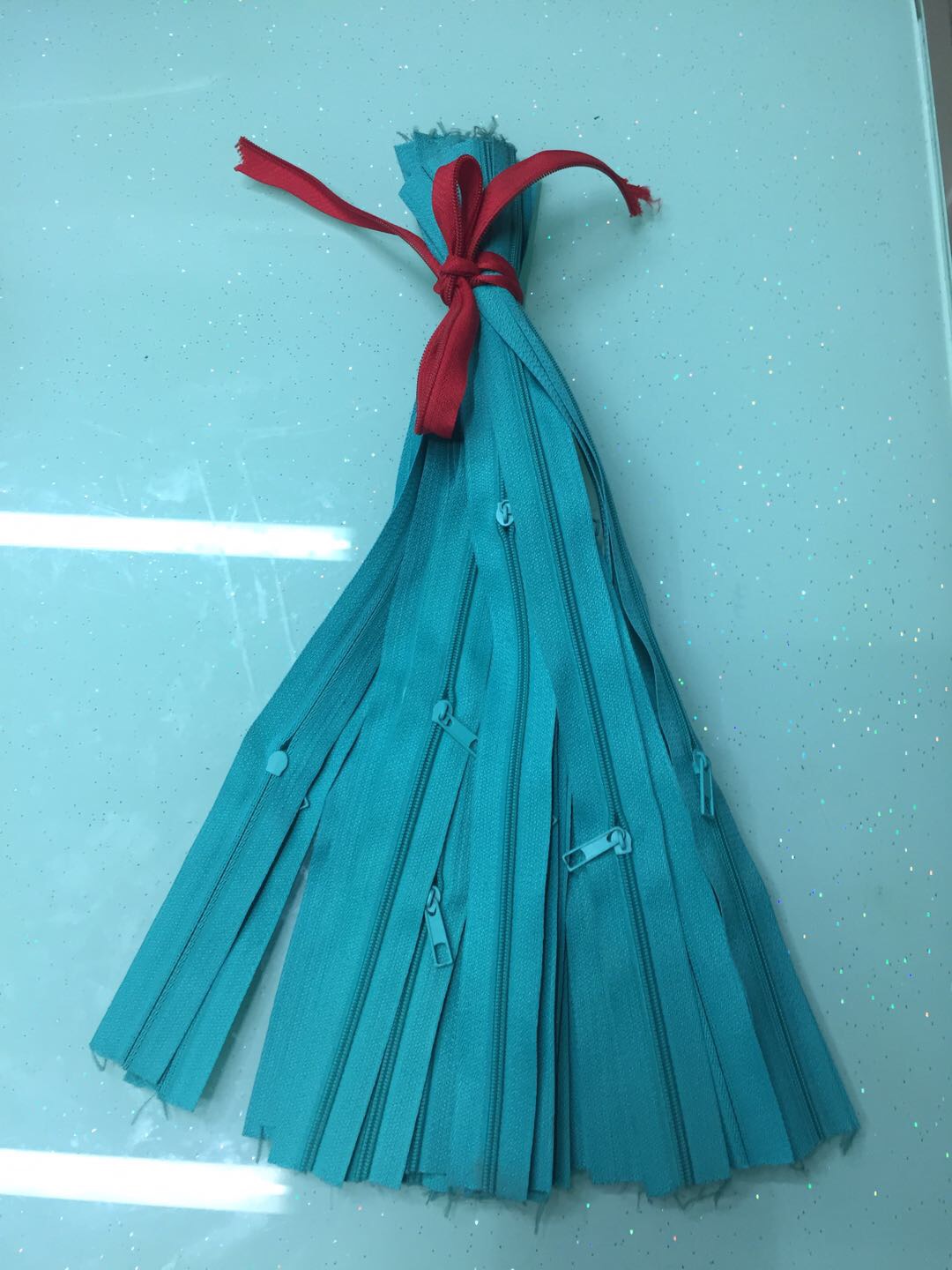

A whisper-thin invisible zipper seamlessly integrated into luxurious fabric—precision engineered for elegance.

When the sewing needle first catches light at dawn, it’s not just stitching fabric—it’s shaping the future of fashion. And nestled within that quiet moment is a detail so subtle, yet so transformative: the invisible zipper. From haute couture runways to everyday silhouettes, this unassuming closure has quietly redefined what we consider “perfect” in garment construction. It’s not about hiding function—it’s about elevating form. In an era where minimalism speaks volumes, the demand for seamless aesthetics has never been higher. But achieving true invisibility without sacrificing strength? That’s where material science meets design ingenuity.

The Material Revolution: Why Nylon Resin Is Redefining Closure

High-magnification view reveals the precision-engineered teeth of nylon resin zippers—uniform, flexible, and flawlessly interlocked.

Gone are the days when metal zippers ruled by default. While strong, they often add unwanted weight, create bulk, or react to moisture. Standard nylon zippers, though lighter, can lack resilience under stress or prolonged wear. Enter high-strength nylon resin—an advanced composite that blends molecular durability with featherlight flexibility. Unlike traditional materials, resin-based zippers resist corrosion, maintain integrity through repeated washing, and conform effortlessly to curved seams. Their secret lies in polymer alignment during injection molding, creating a tooth profile that’s both pliable and fracture-resistant. The result? A closure that performs like steel but feels like air—ideal for garments where movement and comfort are non-negotiable.

From Factory Floor to Fashion Studio: The Power of Direct Manufacturing

Beneath every flawless zipper pull is a meticulously controlled production journey. Our facility leverages automated injection molding, real-time tension testing, and spectrophotometric color matching to ensure consistency across batches. By cutting out middlemen, we eliminate markup layers that inflate costs without adding value. This direct-to-designer model empowers emerging labels and independent creators to access industrial-grade quality without enterprise-level budgets. No minimum order quantities. No hidden fees. Just pure transparency—from raw granules to final packaging.

More Than Color: Design Your Zipper’s DNA

Pantone-matched invisible zippers in matte black, champagne, deep emerald, and gradient rose gold—each tailored to a designer’s vision.

Customization goes far beyond hue. Want a waterproof coating for performance outerwear? Done. Seeking a soft-touch matte finish for luxury loungewear? Achieved. How about reflective threads for avant-garde eveningwear? Possible. One independent designer recently used a hand-blended ombré zipper as the centerpiece of her capsule collection—a vertical gradient from midnight blue to silver, perfectly mirrored in the seam of each silk slip dress. Customers didn’t just notice the detail—they remembered it. That’s the power of treating even the smallest component as a signature element.

Free Samples Aren’t a Gimmick—They’re a Guarantee

We don’t ask you to take our word for quality. Instead, we invite you to test it. A rising accessories brand once tested three iterations of our samples before launching their first clutch line—one with standard sliders, another with anti-snag coating, and a third with reinforced tape width. Through wash tests, flex cycles, and user trials, they validated smoothness, retention, and long-term reliability. When evaluating your sample, focus on glide resistance (should feel buttery, not stiff), recovery after stretching (no permanent deformation), and colorfastness after simulated laundering. These micro-performances define macro-success.

Where Flexibility Meets Precision: Applications Across Fabrics

Whether embedded in four-way stretch activewear or anchored in tightly woven satin bridal gowns, our resin zippers adapt. On elastic knits, they move *with* the fabric, preventing puckering. In dense weaves, laser-cut tapes ensure clean insertion without fraying. You’ll find them discreetly securing dance costumes, concealing openings in structured handbags, or enabling sleek closures in insulated winter jackets. Each application proves one truth: invisibility doesn’t mean universality—it means intelligent engineering tuned to context.

The Seamstress’s Secret: Elevating Garment Perception

“Clients never say, ‘I love your zipper,’” shares a veteran patternmaker, “but they *do* say, ‘This feels expensive.’” Hidden zippers contribute to that intangible sense of quality. She emphasizes using proper foot pressure and stitch length when installing them—too heavy, and the tape distorts; too fast, and misalignment occurs. Mastering these nuances turns functional necessity into aesthetic triumph.

Designed to Last, Built to Respect the Planet

Sustainability isn’t an afterthought—it’s embedded in our process. We use recyclable nylon resins and optimize mold design to minimize scrap. Water-based dyes reduce chemical runoff, while energy-efficient presses lower carbon output. Looking ahead, we’re piloting bio-based polymers derived from castor oil, paving the way for fully renewable closures. Because true innovation considers not just how something works today—but how it impacts tomorrow.

Your Next Breakthrough Starts with a Seam

Could the next iconic fashion detail be hiding in plain sight—or rather, not in sight at all? If you could make any garment closure disappear, which would you choose? The answer might just reshape your next collection. Explore limitless possibilities, request your free samples today, and discover how the smallest element can make the boldest statement.