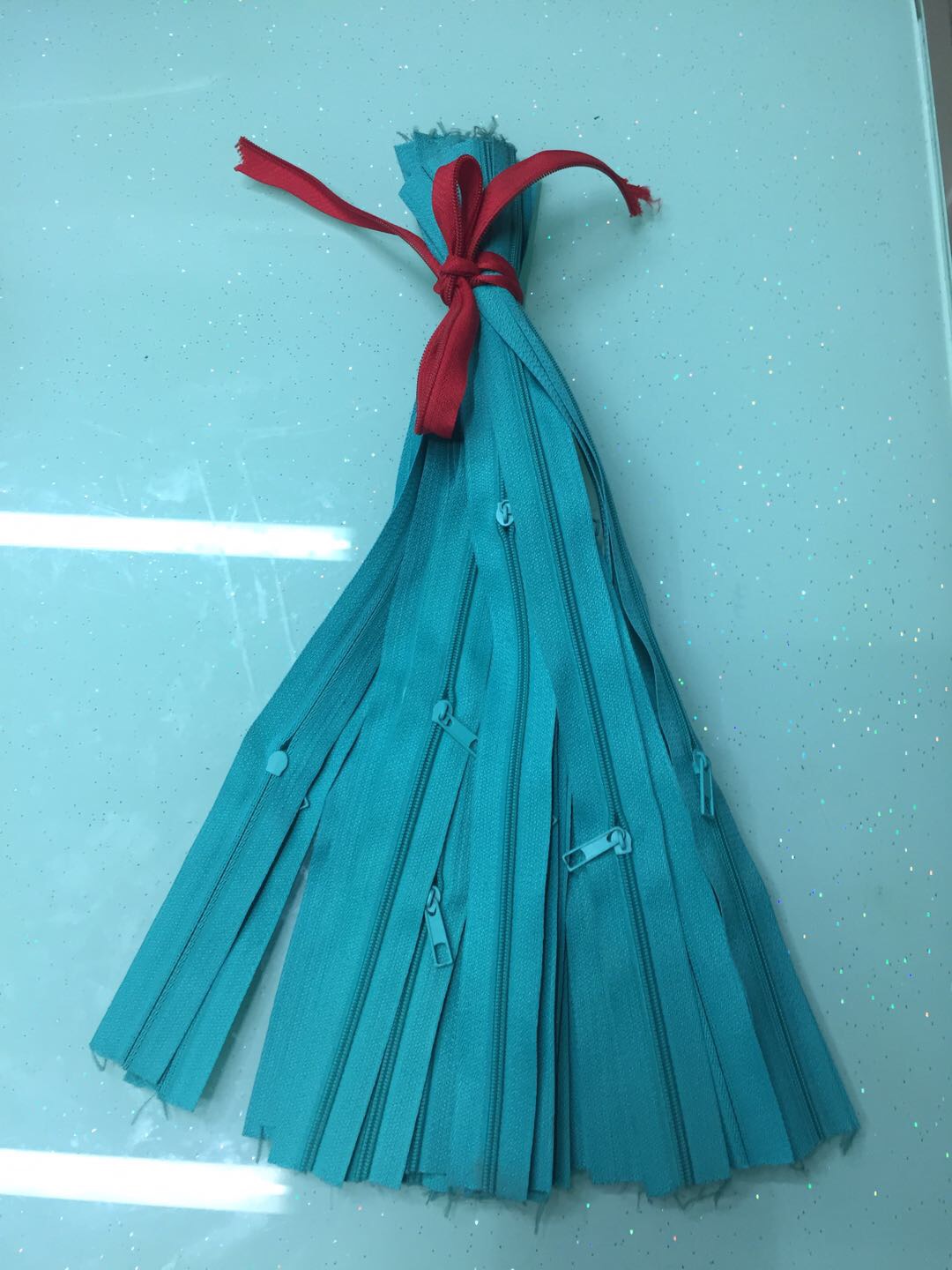

A close-up of a perfectly engineered nylon resin invisible zipper seamlessly integrated into delicate fabric.

When the Invisible Meets Craftsmanship: Redefining the Language of Detail in Fashion

For fashion designers, every stitch tells a story. Once seen merely as functional closures, zippers have evolved into silent storytellers—elements that shape silhouette, influence drape, and elevate design integrity. Among them, the invisible zipper has emerged not just as a closure, but as a statement of intention. It’s the quiet confidence behind a clean back slit, the unseen enabler of effortless elegance. This is where function meets philosophy: the art of making something essential disappear, so the garment can truly shine.

Welcome to the era of “invisible aesthetics”—where what you don’t see speaks volumes about what you do. And at the heart of this movement lies a revolutionary fusion of material science and precision engineering: the custom nylon resin invisible zipper.

Deconstructing the DNA of a Perfectly Invisible Zipper

Not all invisible zippers are created equal. What sets our nylon resin zippers apart begins with their molecular makeup. Unlike traditional polyester or metal alternatives, nylon resin offers an unmatched balance of flexibility, strength, and visual subtlety. Its natural elasticity allows it to move with the fabric, resisting distortion even after repeated use. More importantly, it resists UV degradation and retains color brilliance after countless washes—a critical advantage for garments meant to endure both seasons and styles.

Compare this to metal zippers, which can feel heavy, rust over time, and create visible ridges beneath thin fabrics. Or standard polyester versions that often stiffen or fade. Our resin-based design stays lightweight, smooth, and visually neutral—vanishing into the weave like a whisper.

The magic continues at the tooth level. Precision-molded interlocking teeth create a seamless bond when closed, lying completely flat against the fabric. When stitched correctly, the tape blends invisibly into the seam, creating the illusion that the garment opens by design—not necessity.

Seamless integration: The zipper disappears into the side seam of a high-end dress, preserving the clean lines of the design.

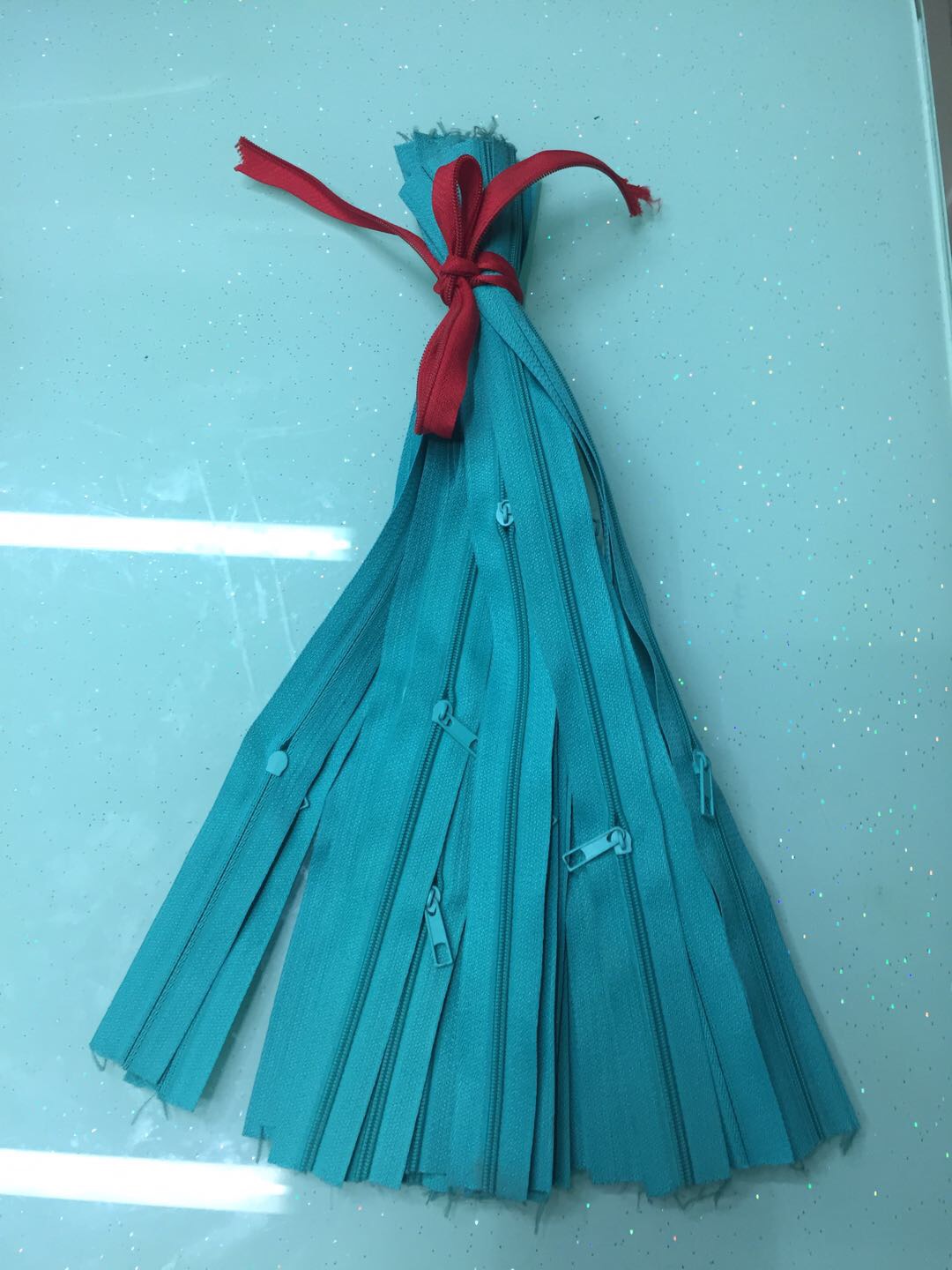

Customization Beyond Color: Your Brand’s Secret Signature

True differentiation lies in the details only you control. That’s why we offer full customization—from exact PANTONE® color matching to specialized surface finishes like matte, glossy, or pearlescent coatings. Whether your brand leans minimalist or maximalist, your zipper can reflect that identity down to the last shimmer.

We support small-batch development, empowering independent designers and agile fashion labels to prototype without minimum order pressure. One emerging womenswear brand, for instance, used a custom deep emerald resin zipper with a soft-touch matte finish to unify their capsule collection. The result? A subtle yet consistent brand signature that customers began to recognize—even before seeing the label.

From Sketch to Sample in 72 Hours: Speed Without Sacrifice

In today’s fast-moving fashion landscape, waiting weeks for a sample isn’t innovation—it’s obstruction. By cutting out intermediaries and connecting designers directly with manufacturers, we’ve streamlined the sampling process to under three days.

Here’s how it works: You submit your specifications—length, color, finish, puller style—and within hours, our production team begins prep. Material is cut, molded, assembled, and inspected—all under one roof. Within 72 hours, your custom zipper sample ships with full tracking. This rapid turnaround empowers seasonal collections, limited drops, and real-time trend responses, turning concept into tangible proof faster than ever.

Endless possibilities: A spectrum of custom-colored nylon resin zippers ready for integration into diverse designs.

The Science Behind Longevity: Built to Withstand Time and Tide

Beauty means nothing without durability. Every batch undergoes rigorous lab testing: tensile strength checks in dry and wet conditions, 10,000-cycle friction simulations, and heat-setting evaluations to ensure dimensional stability. Real-world results confirm what the labs predict—garments equipped with our zippers maintain flawless operation after more than 300 industrial laundry cycles, with no fraying, snagging, or loss of glide.

Sewing Sustainability into the Seam

Fashion’s future must be responsible. That’s why we’re advancing the use of recyclable nylon resins and pursuing third-party environmental certifications. Our manufacturing process leverages energy-efficient molding technology and closed-loop water systems, significantly reducing carbon emissions and waste. For brands committed to ESG goals, these zippers aren’t just functional—they’re foundational to a sustainable supply chain.

Designer’s Tip: Elevating Garments with Invisible Intelligence

Think beyond the center back. Try placing an invisible zipper along a side seam to create a hidden slit that reveals movement. Use one internally to allow access to linings or padding—ideal for convertible coats or structured silhouettes. Or align multiple zippers diagonally across a panel to guide the eye and add architectural interest. On sheer fabrics like chiffon, opt for fine-gauge thread and a narrow foot; on knits, pre-stabilize the seam to prevent stretching. With the right technique, the zipper becomes part of the design language itself.

Cutting Through the Supply Chain Fog

Traditional sourcing routes often involve layers of brokers, markups, and miscommunication. Going direct eliminates guesswork. You speak to the engineers, not sales reps relaying secondhand info. Costs become predictable, timelines transparent, and collaboration immediate. This isn’t just efficiency—it’s empowerment.

The Next Breakout Collection Starts with What No One Sees

In a world saturated with sameness, true distinction hides in the details. A custom nylon resin invisible zipper may never be noticed—but its absence would be felt instantly. It’s the silent assurance of quality, the invisible thread between vision and execution.

Stop settling for off-the-shelf closures. Start building your brand’s identity into every seam. Submit your first custom request today and experience the transformation—from standard component to signature element—in just 72 hours.